CN108367329B - Auxetic structures with angled slots in engineered patterns for custom NPR characteristics and improved cooling performance - Google Patents

Auxetic structures with angled slots in engineered patterns for custom NPR characteristics and improved cooling performance Download PDFInfo

- Publication number

- CN108367329B CN108367329B CN201680012297.0A CN201680012297A CN108367329B CN 108367329 B CN108367329 B CN 108367329B CN 201680012297 A CN201680012297 A CN 201680012297A CN 108367329 B CN108367329 B CN 108367329B

- Authority

- CN

- China

- Prior art keywords

- elongated apertures

- elongated

- top surface

- apertures

- npr

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/002—Wall structures

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/02—Continuous combustion chambers using liquid or gaseous fuel characterised by the air-flow or gas-flow configuration

- F23R3/04—Air inlet arrangements

- F23R3/06—Arrangement of apertures along the flame tube

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C19/00—Alloys based on nickel or cobalt

- C22C19/03—Alloys based on nickel or cobalt based on nickel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R2900/00—Special features of, or arrangements for continuous combustion chambers; Combustion processes therefor

- F23R2900/00005—Preventing fatigue failures or reducing mechanical stress in gas turbine components

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R2900/00—Special features of, or arrangements for continuous combustion chambers; Combustion processes therefor

- F23R2900/00014—Reducing thermo-acoustic vibrations by passive means, e.g. by Helmholtz resonators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R2900/00—Special features of, or arrangements for continuous combustion chambers; Combustion processes therefor

- F23R2900/03041—Effusion cooled combustion chamber walls or domes

Abstract

Auxetic structures, effusion cooled auxetic sheets, systems and devices having auxetic structures, and methods of using and methods of making auxetic structures are disclosed. Auxetic structures are disclosed that include an elastically rigid body having opposing top and bottom surfaces. A first plurality of elongated apertures and a second plurality of elongated apertures extend through the elastically rigid body from the top surface to the bottom surface. The first plurality of elongated apertures extends transversely relative to the second plurality of elongated apertures. The first and/or second plurality of elongated apertures are angled obliquely to a top surface of the elastically rigid body. The elongated apertures are cooperatively configured to provide a desired cooling performance while exhibiting a stress reduction through Negative Poisson's Ratio (NPR) behavior under macroscopic planar loading conditions. For example, the auxetic structure may exhibit an effusion cooling effect of about 30 to 50Eta and a poisson's ratio of about-0.2% to-0.9%.

Description

Cross Reference to Related Applications

This application claims priority from us provisional patent application No. 62/118,826 filed on day 20/2/2015 and us provisional patent application No. 62/101,840 filed on day 9/1/2015, each of which is incorporated by reference herein in its entirety.

Technical Field

The present disclosure relates generally to porous materials and honeycomb (cellular) solids having tailored isotropic and anisotropic poisson's ratios. More particularly, aspects of the present disclosure relate to auxetic structures having engineered patterns exhibiting Negative Poisson's Ratio (NPR) characteristics, and systems, methods, and devices using the same.

Background

When compressing a material along a particular axis, it is most often observed that the material stretches in a direction transverse to the applied axial load. Conversely, when a tensile load is applied along an axis transverse to the axis of contraction, most of the material contracts along a particular axis. A material property that characterizes this property is called poisson's ratio, which can be defined as the negative ratio of transverse/lateral strain to axial/longitudinal strain under axial loading. Most materials are characterized by a positive poisson's ratio of about 0.5 for rubber, about 0.3 for aluminum, brass and steel, and about 0.2 for glass.

On the other hand, a material with a negative poisson's ratio will contract (or expand) in the transverse direction when compressed (or stretched) in the axial direction. Materials that exhibit negative poisson's ratio characteristics are commonly referred to as "auxetic" materials. Many findings indicate that auxetic properties involve the interaction between the microstructure of the material and its deformation. Such examples are provided by the following findings: metals with cubic lattices, natural layered ceramics, ferroelectric polycrystalline ceramics, and zeolites can all exhibit negative poisson's ratio characteristics. In addition, several geometries and mechanisms have been proposed to achieve negative poisson's ratio values, including foams with a concave (reentrant) structure, graded laminates, polymer foams, and metal foams. The negative poisson's ratio effect is also demonstrated at the micro scale using composite materials assembled by soft lithography, and at the nano scale using a sheet assembly of carbon nanotubes.

A significant challenge in assembling auxetic materials is that the materials typically involve an embedded structure with an entangled geometry within the host matrix. Thus, the manufacturing process encounters a bottleneck in the practical development towards applications. The basic structure of many auxetic materials is a honeycomb solid structure. Studies on the deformation of these materials are a relatively mature field, mainly emphasizing the effect of the buckling phenomenon on load bearing capacity and energy absorption under compressive loads. Recently, the combined results of experimental and numerical studies demonstrate that mechanical instabilities in 2D periodic porous structures can cause sharp transitions in the original geometry. Specifically, it was found that uniaxial loading of a square array of circular holes in an elastomeric matrix resulted in an alternating mutually orthogonal elliptical pattern when the array was under load. This is due to elastic instability above a critical value of the applied strain. The geometric reorganization observed under instability is reversible and repeatable, and this occurs over a narrow range of applied loads. Furthermore, it is shown that the pattern transitions cause a unidirectional negative poisson's ratio characteristic of the 2D structure, i.e. this only occurs under compression.

U.S. Pat. No. 5,233,828 ("the' 828 patent") shows an example of an engineered void structure, i.e., a combustor liner or "heat shield" for high temperature applications. Combustor liners are commonly used in the combustion section of gas turbines. The combustor liner may also be used in the exhaust section or other sections or components of a gas turbine, such as turbine blades. In operation, the combustor combusts gases at extremely high temperatures (e.g., about 3,000 ° F or higher). To prevent this intense heat from damaging the combustor prior to being discharged to the turbine, a combustor liner is provided inside the combustor to insulate the surrounding engine. To minimize temperature and pressure differentials across the combustor liner, cooling features are typically provided, as shown in the' 828 patent, in the form of spaced cooling holes arranged in a continuous pattern. As another example, U.S. Pat. No. 8,066,482B2 shows an engineered structural member with elliptical cooling holes to enhance cooling of a desired region of a gas turbine while reducing stress levels in and around the cooling holes. European patent EP0971172a1 also shows another example of a perforated liner for the combustion zone of a gas turbine. However, all of the above patent documents are not provided with disclosure as examples of exhibiting auxetic characteristics or being designed to provide NPR effects.

U.S. patent application publication No. 2010/0009120a1 discloses a variety of varying periodic structures that include elastic or elastoplastic periodic solids that undergo a structural configuration transition upon application of a critical macroscopic stress or strain. The transformation changes the geometric pattern, changing the spacing and shape of features in the varying periodic structure. Once the critical macroscopic stress or strain is removed, these elastic periodic solids recover their original form. In contrast, U.S. patent application publication No. 2011/0059291a1 discloses structured porous materials in which the porous structure provides tailored poisson's ratio characteristics. These porous structures are composed of a pattern of elliptical or quasi-elliptical voids in an elastic sheet that is tuned via the deformation mechanics of the voids and the deformation mechanics of the material to provide a negative or zero poisson's ratio. All of the above-mentioned patent documents are each incorporated by reference herein in their entirety and for all purposes.

Summary of The Invention

Aspects of the present disclosure relate to auxetic structures having a repeating pattern of elongated apertures (also referred to herein as "voids" or "slots") designed to provide desired Negative Poisson's Ratio (NPR) characteristics and improved cooling performance. Unlike prior art NPR void shapes, which extend through the plane of the structural material, through the thickness of the material in a direction perpendicular to the plane of the material, the NPR voids disclosed herein pass through the thickness of the material at an oblique angle to the plane of the material. These angled void configurations enhance the cooling performance of the structure while retaining low porosity and providing the desired NPR characteristics. Other aspects of the present disclosure relate to a multifunctional NPR structure having angled air passages in the hot section of a gas turbine. Other aspects relate to gas turbine combustors having walls made of materials with designed angled clearance features that provide specific thermal, damping, and/or acoustic functions. Such functions include, for example, acoustic attenuation (or noise damping), stress reduction (or load damping), and thermal cooling (or thermal damping).

In accordance with aspects of the present disclosure, auxetic structures having angled NPR slots are disclosed. In an example, the auxetic structure includes an elastically rigid body, such as a metal sheet or other sufficiently elastic solid material, having opposing top and bottom surfaces. The first and second pluralities of elongated apertures extend through the elastically rigid body from the top surface to the bottom surface. The first plurality of elongated apertures extends transversely (e.g., orthogonally) relative to the second plurality of elongated apertures. The first and/or second plurality of elongated apertures are angled obliquely to the top and/or bottom surfaces of the elastically rigid body. In an example, each slot passes through the thickness of the sheet at an oblique angle (e.g., about 40 to 70 degrees) to the plane of the material. The elongated apertures are cooperatively configured to provide a desired or minimum cooling performance while exhibiting stress reduction through Negative Poisson's Ratio (NPR) behavior under macroscopic planar loading conditions. For example, the elongated apertures are designed with a predetermined porosity, a predetermined pattern, and/or a predetermined aspect ratio to achieve desired NPR characteristics. The auxetic structure may exhibit an effusion cooling effect of about 30% to 50%, a porosity of about 0.3% to about 9%, and a poisson's ratio of about-0.2% to-0.9%. The cooling effect (Eta) can be defined as the difference between the hot gas temperature and the wall temperature in the presence of the cooling device divided by the difference between the hot gas temperature and the temperature of the supplied cooling gas: eta — wall)/(T _ hot gas-T _ coolant).

According to other aspects of the present disclosure, effusion-cooled auxetic sheet structures are features. In an example, an effusion cooled auxetic sheet structure is presented that includes a metal sheet having opposing top and bottom surfaces. The first and second pluralities of elongated apertures extend through the metal sheet from the top surface to the bottom surface. The first plurality of elongated apertures has a first set of geometric characteristics and is arranged in a first pattern. Likewise, the second plurality of elongated apertures have a second set of geometric characteristics and are arranged in a second pattern. The first plurality of elongated apertures is orthogonally oriented with respect to the second plurality of elongated apertures. Each elongated aperture is angled obliquely relative to the top surface of the elastically rigid body. The geometry and pattern of the first plurality of elongated apertures is cooperatively configured with the geometry and pattern of the second plurality of elongated apertures to provide a desired or minimal cooling performance while exhibiting Negative Poisson's Ratio (NPR) characteristics under macroscopic planar loading conditions.

Other aspects of the present disclosure relate to methods of making auxetic structures and methods of using auxetic structures. In an example, a method for manufacturing an auxetic structure is presented. The method comprises the following steps: providing an elastically rigid body having opposing top and bottom surfaces; adding to the elastic rigid body a first plurality of apertures extending through the elastic rigid body from the top surface to the bottom surface, the first plurality of apertures arranged in rows and columns; and adding to the elastic rigid body a second plurality of apertures extending through the elastic rigid body from the top surface to the bottom surface, the second plurality of apertures arranged in rows and columns. Each of the first and/or second plurality of elongated apertures is angled obliquely to a top surface of the elastically rigid body. The first and second plurality of apertures are cooperatively configured to provide a desired or minimum cooling performance while exhibiting Negative Poisson's Ratio (NPR) characteristics under macroscopic planar loading conditions. For example, the elongated apertures are designed with a predetermined porosity, a predetermined pattern, and/or a predetermined aspect ratio to achieve desired NPR characteristics. The auxetic structure may exhibit an effusion cooling effect of about 30% to 50% and a poisson's ratio of about-0.2% to-0.9%. The elastically rigid body may take various forms, such as a metal sheet or other sufficiently elastic solid material.

The above summary of the present invention is not intended to represent each embodiment, or every aspect, of the present disclosure. Rather, the foregoing summary merely provides an exemplification of some of the novel aspects and features set forth herein. The above features and advantages and other features and advantages of the present disclosure, which are believed to be inventive either individually or in any combination, are readily apparent from the following detailed description of exemplary embodiments and modes for carrying out the invention when taken in connection with the accompanying drawings and appended claims.

Brief Description of Drawings

Fig. 1 is a plot of nominal strain versus poisson's ratio illustrating poisson's ratio characteristics of a representative structure having elongated through-holes in accordance with aspects of the present disclosure.

Fig. 2A-2C are examples of representative structures in fig. 1 that correspond to particular data points in the graph.

Fig. 3A and 3B are side and perspective view examples, respectively, of an angled NPR S slot, according to aspects of the present disclosure.

Fig. 4A-4D are perspective view examples of other angled NPR slots, according to aspects of the present disclosure.

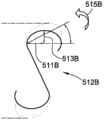

Fig. 5A and 5B are plan view examples of angled NPR S slots and tilted NPR Z slots, respectively, with variable cover rotation, according to aspects of the present disclosure.

Fig. 6A-6D are plan view examples of angled NPR S slots exhibiting 0, 45, 55, and 65 angle angles, respectively, according to aspects of the present disclosure.

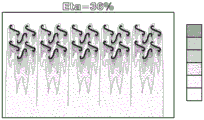

7A-7C are graphical examples of cooling characteristics of a non-NPR vertical cooling hole, a vertical NPR cooling slot, and an angled NPR cooling slot, respectively, in accordance with aspects of the present disclosure.

The present disclosure is susceptible to various modifications and alternative forms, and certain representative embodiments have been shown by way of example in the drawings and will be described in detail herein. It should be understood, however, that the inventive aspects of the present disclosure are not limited to the particular forms illustrated in the drawings. Rather, the disclosure is to cover all modifications, equivalents, combinations, and sub-combinations, and alternatives falling within the spirit and scope of the invention as defined by the following appended claims.

Detailed description of illustrative embodiments

The present disclosure is susceptible to embodiments in various forms. There are shown in the drawings, and herein will be described in detail, representative embodiments with the understanding that the present disclosure is to be considered an exemplification of the principles of the disclosure, and is not intended to limit the broad aspect of the disclosure to the embodiments illustrated. In such cases, elements and limitations that are disclosed, for example, in the abstract, summary, and detailed description section, but not explicitly recited in the claims, are not intended to be incorporated into the claims by implication, inference, or otherwise, either individually or collectively. For purposes of this detailed description, unless explicitly negated or logically disabled: singular encompasses plural and vice versa; and the word "including" or "having" means "including but not limited to". Moreover, approximating words, such as "about," nearly, "" substantially, "" about, "and the like, may be used herein in the sense of, for example," being in, near, or approximately "or" within 3% to 5% of.

Aspects of the present disclosure relate to auxetic structures comprising a repeating pattern of angled slits that provide Negative Poisson's Ratio (NPR) characteristics when under macroscopic loading. Poisson's ratio (or "poisson coefficient") may generally represent the ratio of transverse contraction strain to longitudinal extension strain in a stretched object. Most materials have a generally positive poisson's ratio, including many alloys, polymers, polymer foams, and honeycomb solids, which become thinner in cross-section when stretched. The auxetic structures disclosed herein exhibit negative poisson's ratio characteristics.

According to aspects of the disclosed concept, when the auxetic structure is compressed along one axis (e.g., in the Y-direction), the coaxial strain causes a moment about the center of each cell due to the arrangement of adjacent holes. This, in turn, causes the unit to rotate. Each cell rotates in a direction opposite to that of its immediate neighbors. This rotation causes the distance of the transverse axis (X direction) between horizontally adjacent cells to decrease. That is, compressing the structure in the Y direction causes it to contract in the X direction. Conversely, a pulling force in the Y direction results in an extension in the X direction. This simulates the properties of auxetic materials on the scale of the overall structure. Many of the structures disclosed herein are comprised of conventional materials. Thus, the undoped material itself may have a positive poisson's ratio, but the structure is modified by introducing the angled slot pattern disclosed herein, then the structure appears to have a negative poisson's ratio.

Fig. 1 is a plot of Poisson's Ratio (PR) versus nominal strain illustrating poisson's ratio characteristics of three representative void structures shown in fig. 2A-2C. The graph of fig. 1 shows the poisson's ratio of each test strip under load. At some level of deformation, the "instantaneous" PR can be determined and plotted against a parameter (e.g., nominal strain) that represents the level of deformation. When the designer has a desired NPR for the intended application, the level of deformation corresponding to the desired PR can be determined and the geometry of the holes under this condition can be determined. The hole shape pattern can then be machined (fabricated) on the stress free portion to achieve an assembly with the desired PR.

As shown in fig. 2B and 2C, the NPR hole pattern may consist of horizontally and vertically oriented elongated holes (also referred to as "holes" or "voids" or "slots") as shown by oval through slots. These elongated holes are arranged in horizontal and vertical lines (e.g., rows and columns of a square array in fig. 2B) in the following manner: the vertical lines are equally spaced and the horizontal lines are equally spaced in two dimensions (i.e., Δ x ═ Δ y). The center of each slot is at the intersection of the two lines. Horizontally oriented and vertically oriented slots alternate on vertical and horizontal lines such that any vertically oriented slot is surrounded by horizontally oriented slots (and vice versa) while the next vertically oriented slot appears on both diagonal lines. These voids may also serve as cooling holes and/or damping holes and, due to their arrangement, may also serve as stress reduction features. One or more of the slots shown herein may be replaced by elongated NPR protrusions or hemispherical dimples.

Also disclosed are gas turbine combustors made from one or more walls of material having any of the particular auxetic structure configurations disclosed herein. In some embodiments, angled slits are created directly in the metal body in an unstressed state such that the pores are identical in shape to the collapsed void shapes found in rubber under external loads in order to obtain NPR characteristics in the metal body without collapse of the metal structure in fabrication. Various fabrication approaches may be used to repeat the void pattern in the metal component. Manufacturing does not necessarily contain buckling as one of the process steps. The auxetic structures disclosed herein are not limited to combustor walls; rather, these features may be incorporated into other portions of the turbine (e.g., blades, etc.).

In conventional combustor walls, the holes for cooling air flow and damping also serve as stress concentrators. In some disclosed embodiments, when the wall material at the hot spot is pressed against its surrounding material, for example in a vertical direction, the negative poisson's ratio will cause the wall material to contract in a horizontal direction, and vice versa. This characteristic will significantly reduce the stress at the hot spot. This effect is stronger than the effect of just reducing the stiffness. The stress at the hot spot is reduced by, for example, 50%, which in turn results in an increase in stress fatigue life of several orders of magnitude. The stress reduction caused by the NPR characteristic does not increase the air loss of the combustor wall. In this way, longer life may be used or the wall material may be replaced with cheaper materials to reduce raw material costs.

It has also been demonstrated that replacing the circular burner cooling holes with a portion of 2% to 3% elongated and angled air channels reduces the thermomechanical stresses by at least five times while maintaining the cooling and damping performance. For example, elliptical cooling holes in the combustor have been expected to result in a five-fold reduction in worst case principal stresses. Thus, the NPR characteristics are induced, adding other functionality to the cooling holes of the combustor, as the NPR characteristics produce a five-fold reduction in the worst principal stresses compared to conventional cooling holes. In stress fatigue of combustor specific superalloys, halving the component stresses increases the fatigue life by more than an order of magnitude. IN some embodiments, the superalloy can be a nickel-based superalloy, such as Inconel (e.g., IN100, IN600, IN713), Waspaloy, Rene alloys (e.g., Rene 41, Rene 80, Rene 95, Rene N5), Haynes alloys, Incoloy, MP98T, TMS alloys, and CMSX (e.g., CMSX4) single crystal alloys.

It has been shown that optimized porosity provides increased cooling functionality. As used herein, "porosity" may be defined to mean the surface area A of the poresADivided by the surface area of the structure ASOr porosity ═ AA/AS. In some embodiments, it is desirable for the porosity of a given void structure to be from about 0.3% to about 9.0%, or in some embodiments, from about 1% to about 4%, or in some embodiments, about 2%. In contrast, many prior art arrangements require 40% to 50% porosity.

There may be a predetermined optimum aspect ratio for the elongated holes to provide the desired NPR characteristics. As used herein, the "aspect ratio" of a hole may be defined to mean the length of the hole divided by the width of the hole, or the length of the major axis of the hole divided by the length of the minor axis of the hole. In some embodiments, it is desirable that the aspect ratio of the pores be from about 5 to about 40, or in some embodiments, from about 20 to about 30. The optimum NPR may include, for example, from about-0.2 to about-0.9 PR, or for some embodiments, about-0.5. Aspects of the disclosed concept can be demonstrated on a pattern of structures produced with a pattern length scale of millimeters, and are equally applicable to structures having the same periodic pattern with smaller length scales (e.g., micrometer, submicrometer, and nanometer length scales) or larger length scales, so long as the unit cell is suitable for the structure.

Turning next to fig. 3-6, various examples of angled slot aux structures exhibiting desired NPR characteristics and enhanced cooling performance according to the present disclosure are shown. For example, fig. 3A and 3B illustrate an auxetic structure, generally designated 300, which utilizes an alternating pattern of elongated, asymmetric slits. The aforementioned slots are elongated, each having a major axis (e.g., length) therein that is greater than and perpendicular to a minor axis (e.g., width). As shown, auxetic structure 300 includes an elastically rigid body 310, which may be in the form of a sheet of metal or other solid material having suitable elasticity to substantially or completely return to its original form once macroscopic loading conditions are sufficiently reduced or eliminated. The elastically rigid body 310 has a first (top) surface 314 in opposing spaced relation to a second (bottom) surface 316. Assembled into the elastically rigid body 310 are a first plurality of S-shaped through slots (also referred to herein as "holes" or "voids" or "slots"), referred to herein as slots 312, that extend through the body 310 from a top surface 314 to a bottom surface 316. A second plurality of S-shaped channels/holes, denoted herein as slots 318, also extend through the elastically rigid body 310 from the top surface 314 to the bottom surface 316. The pattern of elongated holes present in the elastic rigid body 310 may be similar in arrangement to that seen in fig. 2B and 2C.

The S-shaped channels 312, 318 are arranged in an array or matrix of rows and columns, and the first plurality of elongated apertures 312 extend transversely relative to the second plurality of elongated apertures 318. It should be noted that the dashed lines representing the internal structural configuration of slot 318 have been omitted from fig. 3A and 3B for clarity to better illustrate the internal structural configuration of slot 312. For at least some embodiments, the rows are equally spaced from each other, and likewise, the columns are equally spaced from each other. According to the embodiment illustrated in fig. 3A and 3B, for example, each row and each column includes vertically oriented S-shaped through slots 312 interleaved with horizontally oriented S-shaped through slots 318. In practice, each vertically oriented channel 312 is adjacent to a horizontally oriented channel 318 on four sides, while each horizontally oriented channel 318 is adjacent to a vertically oriented channel 312 on four sides. With this arrangement, the minor axes of the first plurality of S-shaped channels 312 are parallel to the rows of the array, whereas the minor axes of the second plurality of S-shaped channels 318 are parallel to the columns of the array. Thus, the long axis of the through slots 318 (parallel to the rows of the array) is perpendicular to the long axis of the through slots 312 (parallel to the columns of the array). It is contemplated that other patterns and arrangements for achieving stress reduction through NPR characteristics are within the scope and spirit of the present disclosure.

The illustrated pattern of elongated, angled slots provides a particular porosity (e.g., about 0.3% to about 9.0% porosity) and desired cooling performance (e.g., about 30% to 50% effusion cooling effect) while exhibiting desired negative poisson's ratio characteristics (e.g., PR of about-0.2 to about-0.9) under macroscopic planar loading conditions (e.g., when tension or compression is applied in the plane of the sheet). When the auxetic structure 300 is pulled, for example, via a pulling force FTWhen stretched along the vertical axis Y, the axial strain in the vertical direction results in a moment about the center of each cell, which causes the cell to rotate. The cell may be comprised of two laterally adjacent vertical slots aligned with two vertically adjacent horizontal slots to form a square cell. Each cell rotates in a direction opposite to that of its immediate neighbors. This rotation increases the X-direction distance between horizontally adjacent cells, such that stretching the structure in the Y-direction causes it to stretch in the X-direction. The first plurality of S-shaped channels 312 have (first) engineered geometric properties, including predetermined geometry and predetermined aspect ratio, while the second plurality of S-shaped channels 318 have (second) engineered geometric properties, including predetermined geometry and predetermined aspect ratio, that are cooperatively configured with (third) engineered geometric properties of the hole pattern, including NPR slot density and cell arrangement, to achieve desired NPR properties under macro-load conditions.

Each slot in the first plurality of elongated S-shaped channels 312 and/or the second plurality of elongated S-shaped channels 318 may be angled obliquely with respect to the top surface 314 or the bottom surface 316, or both, of the elastically rigid body 310 of the auxetic structure 300. In an example, a slot 312 is shown in fig. 3A that passes through the entire thickness of the material at an oblique angle to the horizontal plane of the material. For at least some embodiments, the angle Φ of each bore with top surface 314 and bottom surface 316 of body 310 of the auxetic structure is about 20 to 80 degrees, or in some embodiments, about 40 to 70 degrees. These macroscopically patterned NPR voids, such as S-angled slots (fig. 3A, 3B, 4A, and 5A), or, likewise, I-angled slots (fig. 4B), barbell-shaped angled slots (fig. 4C), oval-shaped angled slots (fig. 4D), Z-angled slots (fig. 5B), C-angled slots, etc., serve as effusion cooling holes that allow cooling fluid FL to pass through one surface of the auxetic structure, through the body at an oblique angle α, as shown in fig. 3A, and through the opposite surface of the auxetic structure. This configuration enhances film cooling performance compared to conventional cooling slots/holes that are perpendicular to the thickness of the body, thus restricting cooling fluid flow even more. The tilt angle α can be defined as the angle between the incident vector and its projection on the material plane. The tilt angle can be varied in a 360 ° free rotational degree of freedom to achieve many desired combinations of auxetic characteristics and film cooling performance. The cooling effect (Eta) can be represented as a dimensionless value that quantitatively indicates how effectively a fluid flowing through a porous surface protects the surface from high temperature mainstream flow. The cooling effect can be defined as the difference between the hot gas temperature and the wall temperature in the presence of the cooling device divided by the difference between the hot gas temperature and the temperature of the supplied cooling gas: eta — wall)/(T _ hot gas-T _ coolant).

Patterned angled NPR slot features, such as those disclosed in fig. 3-6, have been shown to cool significantly better than conventional right-angled (vertical) circular holes and cooling slots because the internal surface area of the slot is greater than the internal surface area of a vertical circular hole or slot. For example, the cooling effect of the insulating film is also improved compared to conventional vertical cooling holes and slots, due to a more even distribution of cooling air over the surface and reduced penetration of coolant jets into the flow of the main flow. This can be seen when comparing the cooling characteristics of the representative non-NPR vertical cooling holes (Eta ═ 17%), vertical NPR cooling slots (Eta ═ 36%), and angled NPR S slots (Eta ═ 44%) of fig. 7A, 7B, and 7C, respectively. Angled NPR slot films may benefit from the Coanda (Coanda) effect, which results in better adhesion of the coolant jet to the wall, rather than breaking off and penetrating into the flow of the main flow. This helps to reduce the tilt angle, which in turn reduces coolant spray penetration and improves cooling performance of the NPR slot. From an aerodynamic perspective, the angled NPR slots reduce penetration of the coolant spray due to film cooling, reducing aerodynamic losses compared to perpendicular coolant slot flow. The tilt angle may be varied to achieve a desired combination of auxetic characteristics and film cooling performance.

It has been determined that having angled cooling slots helps provide better coverage of film cooling than vertical cooling holes having inner walls that are perpendicular to the cooling flow. Furthermore, earlier studies have shown that coolant injection from angled NPR slots is more efficient than injection from perpendicular cooling holes, because the mixing process is less intensive for closed films injected from slots. While the high thermal stresses encountered on gas turbine blades and vanes are generally not permitted for the highly elongated slots, the angled NPR slots help reduce or otherwise eliminate the high thermal stresses on the turbine blades/vanes while enhancing film cooling performance. For at least some embodiments, it is generally desirable to minimize surface porosity and the amount of coolant used in the turbine engine; the vertical NPR slots may be replaced with a smaller number of angled NPR slots to minimize porosity. In this case, the cooling flow consumption will be reduced while maintaining the film cooling performance of the effusion slots.

As an exemplary implementation of the disclosed features, a combustor liner with a sheet metal wall may be considered in which the conventional circular effusion holes or vertical effusion slots are replaced with a pattern of angled S-shaped NPR slots forming an auxetic structure. The cooling air fed through these angled S-shaped slots removes heat from the structure and creates an even distribution of cooling air over the surface. These angled slots with increased internal surface area enhance film cooling performance and improve mechanical response. Furthermore, the angled NPR slots can sustain higher flame temperatures and help impart a longer life to the sheet than conventional sheet metal walls with vertical effusion holes.

Illustrated in fig. 4A-4D are perspective view examples of other auxetic structures having angled NPR slots according to aspects of the present disclosure, generally indicated at 400A, 400B, 400C, and 400D, respectively. Although different in appearance, auxetic structures 400A-400D may include any of the features, options, and alternatives described herein with respect to other auxetic structures. Likewise, any auxetic structure disclosed herein may share features, options, and alternatives with other disclosed embodiments, unless explicitly disclaimed or logically prohibited. Auxetic structures 400A-400D each include an elastically rigid body 410A, 410B, 410C, and 410D, respectively, assembled with a plurality of elongated and angled holes 412A, 412B, 412C, and 412D, respectively, arranged in a pattern that provides desired cooling performance while exhibiting predetermined NPR characteristics under macro-plane loading conditions. In fig. 4A, the elongated aperture 412A has an S-shaped plan view profile, whereas in fig. 4B, the elongated aperture 412B has an I-shaped plan view profile that includes a pair of spaced semicircular slots connected by an elongated linear slot. In contrast, the elongated aperture 412D in fig. 4D has an elliptical plan view profile, whereas the elongated aperture 412C in fig. 4C has a barbell-shaped plan view profile that includes a pair of spaced circular bores connected by an elongated linear slot. Any of the aforementioned angled NPR slots can be fabricated by laser cutting, for example, by arranging a linear pattern of NPR slots along an oblique angle to the surface.

With continued reference to fig. 4A-4D, the profile of the angled NPR slot appearing on the outer (top) surface can be designed as a projection of a standard shape, e.g., standard "S" 414A, standard "I" 414B with rounded arms, standard barbell 414C with rounded ends, and standard ellipse 414D. Optionally, the profile of the angled NPR slot appearing on the outer (top) surface may be highly distorted from the original image, e.g., depending on the desired angle and/or orientation of the slot. Fig. 6A-6D illustrate slot distortion on the outer surface of a tubular auxetic structure: FIG. 6A illustrates a vertical NPR S slot exhibiting a 0 degree angle; FIG. 6B illustrates an angled NPR S slot exhibiting a 45 degree angle; FIG. 6C illustrates an angled NPR S slot exhibiting a 55 degree angle; and figure 6D illustrates an angled NPR S slot exhibiting a 65 degree angle.

New NPR slot shapes, such as Z-shaped slot 512A (fig. 5A) and S-shaped slot (fig. 5B), may be developed by reducing cover lengths 511A and 511B and/or cover heights 513A and 513B to provide a horizontal projection similar to existing or "standard" S/Z shapes. The size and shape of the cover can be varied to achieve a desired combination of auxetic characteristics and film cooling performance. The film cooling performance of the angled effusion S-shaped slots, or likewise the Z-shaped slots, can be improved by creating a longer thermal cooling layer over the hot surface. The side area of the slots perpendicular to the flow of the free main flow can be increased by rotating the S-slot cover in a counter-clockwise direction (or clockwise for the Z-slot cover), resulting in a longer thermal cooling layer. The rotational angles 515A and 515B of the cover can be varied to achieve a desired combination of auxetic characteristics and film cooling performance. By rotating the cover of the S-shaped slot in a counter-clockwise direction, the maximum mechanical stress at the top of the cover will be reduced and the film cooling performance of the effusion cell will be improved due to the increased coverage of the thermal cooling layer over the hot surface.

Aspects of the present disclosure also relate to methods of making auxetic structures and methods of using auxetic structures. For example, a method for manufacturing an auxetic structure, such as the auxetic structure described above with respect to fig. 3-6, is presented. The method comprises as an inclusive but non-exclusive set of operations: providing an elastically rigid body, such as the elastically rigid body 310 of fig. 3A and 3B, having opposing top and bottom surfaces; adding a first plurality of apertures, such as the elongated S-shaped slots 312 of fig. 3A and 3B, to the elastically rigid body that extend through the elastically rigid body from the top surface to the bottom surface; and adding a second plurality of holes to the elastically rigid body, such as the elongated S-shaped slot 318 of fig. 3A and 3B, extending through the elastically rigid body from the top surface to the bottom surface. The first plurality of apertures and the second plurality of apertures are arranged in rows and columns. Each of the first plurality of apertures and/or the second plurality of apertures is angled obliquely to a top surface of the elastically rigid body. The first plurality of apertures and the second plurality of apertures are cooperatively configured to provide a predetermined cooling performance while exhibiting a predetermined Negative Poisson's Ratio (NPR) characteristic under macroscopic planar loading conditions. For example, the elongated apertures are designed with a predetermined porosity, a predetermined pattern, and/or a predetermined aspect ratio to achieve desired NPR characteristics. The auxetic structure may exhibit an effusion cooling effect of about 30% to 50% and a poisson's ratio of about-0.2% to-0.9%. The elastically rigid body may take various forms, such as a metal sheet or other sufficiently elastic solid material.

In some embodiments, the method includes at least those steps recited above and illustrated in the accompanying figures. It is also within the scope and spirit of the present invention to omit steps, include other steps, and/or modify the order noted above. It should also be noted that the foregoing method may represent a single sequence for designing and assembling the auxetic structure. However, it is contemplated that the method will be practiced in a systematic and repetitive manner.

The present invention is not limited to the precise construction and compositions disclosed herein. Rather, any and all modifications, variations, combinations, permutations and variations that become apparent from the above description are within the scope and spirit of the present invention as defined by the appended claims. Moreover, the present concepts expressly include any and all combinations and subcombinations of the foregoing elements and aspects.

Claims (32)

1. An auxetic structure comprising:

an elastically rigid body having opposing top and bottom surfaces and first and second pluralities of elongated apertures extending through the elastically rigid body from the top surface to the bottom surface, the first plurality of elongated apertures extending transversely relative to the second plurality of elongated apertures, at least the first plurality of elongated apertures being at an oblique angle to the top surface of the elastically rigid body, each of the elongated apertures of the first plurality of elongated apertures having an original shape that is offset on the top surface, the original shape being at an oblique angle to the top surface to achieve a distorted shape of the elongated aperture, the distorted shape being a form of a contour on the top surface,

wherein the first and second pluralities of elongated apertures are cooperatively configured to provide a desired cooling performance and exhibit a desired stress performance through Negative Poisson's Ratio (NPR) characteristics under macroscopic in-plane loading conditions, each of the first and second pluralities of elongated apertures having a non-circular shape with a major axis greater than a minor axis.

2. The auxetic structure of claim 1, wherein the second plurality of elongated apertures are obliquely angled to a top surface of the elastically rigid body.

3. The auxetic structure of claim 1, wherein the cooling performance comprises a 30% to 50% effusion cooling effect (Eta), wherein the 30% to 50% effusion cooling effect (Eta) is defined as:

eta ═ T _ hot gas-T _ wall)/(T _ hot gas-T _ coolant)

T _ hot gas is the hot gas temperature, T _ wall is the wall temperature, T _ coolant is the temperature of the supplied cooling gas.

4. The auxetic structure of claim 1, wherein the elongated apertures are designed with a predetermined porosity, a predetermined pattern, or a predetermined aspect ratio, or any combination thereof, to achieve the NPR characteristic.

5. The auxetic structure of claim 1, wherein each of the elongated apertures has an aspect ratio of 5 to 40, wherein the aspect ratio refers to a ratio of a major axis to a minor axis.

6. The auxetic structure of claim 1, wherein the first plurality of elongated apertures or the second plurality of elongated apertures, or both, each have an S-shaped plan-view profile.

7. The auxetic structure of claim 1, wherein the first plurality of elongated apertures or the second plurality of elongated apertures, or both, each have an elliptical plan-view profile.

8. The auxetic structure of claim 1, wherein the first plurality of elongated apertures or the second plurality of elongated apertures, or both, each have a Z-shaped plan-view profile.

9. The auxetic structure of claim 1, wherein the first plurality of elongated apertures or the second plurality of elongated apertures, or both, each have a barbell-shaped plan view profile comprising a pair of spaced apart bores connected by an elongated slot.

10. The auxetic structure of claim 1, the first plurality of elongated apertures or the second plurality of elongated apertures, or both, each having an I-shaped plan view profile comprising a pair of spaced apart semi-circular slots connected by an elongated slot.

11. The auxetic structure of claim 1, wherein the first and second pluralities of elongated apertures are arranged in an array of rows and columns.

12. The auxetic structure of claim 11, wherein the rows are equally spaced from each other and the columns are equally spaced from each other.

13. The auxetic structure of claim 1, wherein each of the elongated apertures has a major axis perpendicular to a minor axis, the major axes of the first plurality of elongated apertures being substantially perpendicular to the major axes of the second plurality of elongated apertures.

14. The auxetic structure of claim 1, wherein the angle is 40 degrees to 70 degrees.

15. The auxetic structure of claim 1, wherein the NPR characteristic comprises a poisson's ratio of-0.2% to-0.9%.

16. The auxetic structure of claim 1, wherein the elongated apertures have a predetermined porosity of 0.3% to 9%, wherein porosity is defined as

AA/AS

AAIs the surface area of the first and second pluralities of elongated apertures, ASIs the surface area of the top surface.

17. An effusion-cooled auxetic sheet structure comprising:

a sheet of metal having opposing top and bottom surfaces and first and second pluralities of elongated apertures extending through the sheet of metal from the top surface to the bottom surface, the first plurality of elongated apertures having a first set of geometric characteristics and a first pattern, the second plurality of elongated apertures having a second set of geometric characteristics and a second pattern, the first plurality of elongated apertures orthogonally oriented with respect to the second plurality of elongated apertures, each of the first and second pluralities of elongated apertures being angled obliquely with respect to the top surface of the sheet of metal and having a non-circular elongated aperture with a major axis greater than a minor axis, each of the first and second pluralities of elongated apertures having an original shape that is offset on the top surface, the original shape being angled obliquely with respect to the top surface to achieve a distorted shape of the elongated apertures, the distorted shape is in the form of a contour on the top surface,

wherein the first geometric characteristic and pattern of the first plurality of elongated apertures and the second geometric characteristic and pattern of the second plurality of elongated apertures are cooperatively configured to provide a minimum cooling performance characteristic while exhibiting a Negative Poisson's Ratio (NPR) characteristic under macroscopic planar loading conditions.

18. A method of making an auxetic structure, the method comprising:

providing an elastically rigid body having opposing top and bottom surfaces;

adding to the elastic rigid body a first plurality of elongated apertures extending through the elastic rigid body from the top surface to the bottom surface, the first plurality of elongated apertures arranged in rows and columns, each elongated aperture of the first plurality of elongated apertures angled obliquely to the top surface of the elastic rigid body, each elongated aperture having an original shape offset on the top surface, the original shape angled obliquely to the top surface to achieve a distorted shape of the elongated aperture, the distorted shape being a form of a contour on the top surface; and

adding to the elastic rigid body a second plurality of elongated apertures extending through the elastic rigid body from the top surface to the bottom surface, the second plurality of elongated apertures arranged in rows and columns, each of the elongated apertures of the first and second plurality of elongated apertures having a non-circular shape with a major axis greater than a minor axis,

wherein the first and second pluralities of elongated apertures are cooperatively configured to provide cooling performance while exhibiting stress reduction through Negative Poisson's Ratio (NPR) behavior under macroscopic in-plane loading conditions.

19. The method of claim 18, wherein the cooling performance comprises a 30% to 50% effusion cooling effect (Eta), wherein the 30% to 50% effusion cooling effect (Eta) is defined as:

eta ═ T _ hot gas-T _ wall)/(T _ hot gas-T _ coolant)

T _ hot gas is the hot gas temperature, T _ wall is the wall temperature, T _ coolant is the temperature of the supplied cooling gas.

20. The method of claim 18, wherein the elongated apertures are designed with a predetermined porosity, a predetermined pattern, or a predetermined aspect ratio, or any combination thereof, to achieve the NPR characteristic.

21. The method of claim 18, wherein each of the elongated apertures has an aspect ratio of 5 to 40, wherein the aspect ratio refers to a ratio of a major axis to a minor axis.

22. The method of claim 18, wherein the first plurality of elongated apertures or the second plurality of elongated apertures, or both, each have an elliptical plan view profile.

23. The method of claim 18, wherein the first plurality of elongated apertures or the second plurality of elongated apertures, or both, each have an S-shaped plan view profile.

24. The method of claim 18, wherein the first plurality of elongated apertures or the second plurality of elongated apertures, or both, each have a Z-shaped plan view profile.

25. The method of claim 18, wherein the first or second plurality of elongated apertures, or both, each have a barbell-shaped plan view profile comprising a pair of spaced apart bores connected by an elongated slot.

26. The method of claim 18, the first or second plurality of elongated apertures, or both, each having an I-shaped plan view profile comprising a pair of spaced apart semi-circular slots connected by an elongated slot.

27. The method of claim 18, wherein the first and second pluralities of elongated apertures are arranged in an array of rows and columns.

28. The method of claim 27, wherein the rows are equally spaced from each other and the columns are equally spaced from each other.

29. The method of claim 18, wherein long axes of the first plurality of elongated apertures are substantially perpendicular to long axes of the second plurality of elongated apertures.

30. The method of claim 18, wherein the angle is 40 to 70 degrees.

31. The method of claim 18, wherein the NPR characteristic comprises a poisson's ratio of-0.2% to-0.9%.

32. The method of claim 18, wherein the elongated apertures have a predetermined porosity of 0.3% to 9%, wherein porosity is defined as

AA/AS

AAIs the surface area of the first and second pluralities of elongated apertures, ASIs the surface area of the top surface.

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201562101840P | 2015-01-09 | 2015-01-09 | |

| US62/101,840 | 2015-01-09 | ||

| US201562118826P | 2015-02-20 | 2015-02-20 | |

| US62/118,826 | 2015-02-20 | ||

| PCT/US2016/012769 WO2016112368A1 (en) | 2015-01-09 | 2016-01-09 | Auxetic structures with angled slots in engineered patterns for customized npr behavior and improved cooling performance |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN108367329A CN108367329A (en) | 2018-08-03 |

| CN108367329B true CN108367329B (en) | 2021-04-09 |

Family

ID=56356521

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201680012297.0A Active CN108367329B (en) | 2015-01-09 | 2016-01-09 | Auxetic structures with angled slots in engineered patterns for custom NPR characteristics and improved cooling performance |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20180274783A1 (en) |

| EP (1) | EP3242758B1 (en) |

| JP (1) | JP2018508738A (en) |

| CN (1) | CN108367329B (en) |

| CA (1) | CA2973378A1 (en) |

| RU (1) | RU2017126597A (en) |

| WO (1) | WO2016112368A1 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016112369A1 (en) * | 2015-01-09 | 2016-07-14 | President And Fellows Of Harvard College | Auxetic structures with distorted projection slots in engineered patterns to provide npr behavior and improved stress performance |

| EP3655946B1 (en) * | 2017-07-20 | 2022-12-28 | President and Fellows of Harvard College | Acoustic damper for gas turbine combustors |

| CN111299402A (en) * | 2019-11-29 | 2020-06-19 | 湖南飞沃新能源科技股份有限公司 | Hot mound production line |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6427446B1 (en) * | 2000-09-19 | 2002-08-06 | Power Systems Mfg., Llc | Low NOx emission combustion liner with circumferentially angled film cooling holes |

| US7546737B2 (en) * | 2006-01-24 | 2009-06-16 | Honeywell International Inc. | Segmented effusion cooled gas turbine engine combustor |

| US20110059291A1 (en) * | 2009-09-07 | 2011-03-10 | Boyce Christopher M | Structured materials with tailored isotropic and anisotropic poisson's ratios including negative and zero poisson's ratios |

| GB201105790D0 (en) * | 2011-04-06 | 2011-05-18 | Rolls Royce Plc | A cooled double walled article |

| JP6438000B2 (en) * | 2013-03-15 | 2018-12-19 | プレジデント アンド フェローズ オブ ハーバード カレッジ | Low porosity auxetic sheet |

| US9353783B2 (en) * | 2013-03-15 | 2016-05-31 | Rolls-Royce Canada, Ltd. | Auxetic locking pin |

| US9709274B2 (en) * | 2013-03-15 | 2017-07-18 | Rolls-Royce Plc | Auxetic structure with stress-relief features |

-

2016

- 2016-01-09 JP JP2017555433A patent/JP2018508738A/en active Pending

- 2016-01-09 CA CA2973378A patent/CA2973378A1/en not_active Abandoned

- 2016-01-09 WO PCT/US2016/012769 patent/WO2016112368A1/en active Application Filing

- 2016-01-09 RU RU2017126597A patent/RU2017126597A/en not_active Application Discontinuation

- 2016-01-09 US US15/542,636 patent/US20180274783A1/en not_active Abandoned

- 2016-01-09 EP EP16735531.2A patent/EP3242758B1/en active Active

- 2016-01-09 CN CN201680012297.0A patent/CN108367329B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| WO2016112368A1 (en) | 2016-07-14 |

| RU2017126597A3 (en) | 2019-06-04 |

| EP3242758A4 (en) | 2018-07-18 |

| EP3242758A1 (en) | 2017-11-15 |

| RU2017126597A (en) | 2019-02-11 |

| EP3242758B1 (en) | 2019-09-11 |

| JP2018508738A (en) | 2018-03-29 |

| CN108367329A (en) | 2018-08-03 |

| CA2973378A1 (en) | 2016-07-14 |

| US20180274783A1 (en) | 2018-09-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105555657B (en) | Pore structure with duplicate elongated sectional hole patterns | |

| JP6438000B2 (en) | Low porosity auxetic sheet | |

| CN108472913B (en) | Dimple and void mixed auxetic structures with engineered patterns for custom NPR characteristics | |

| US9709274B2 (en) | Auxetic structure with stress-relief features | |

| CN108367536B (en) | Negative Poisson ratio waffle structure | |

| CN108367329B (en) | Auxetic structures with angled slots in engineered patterns for custom NPR characteristics and improved cooling performance | |

| US20170370581A1 (en) | Auxetic Structures With Distorted Projection Slots In Engineered Patterns To Provide NPR Behavior And Improved Stress Performance | |

| CN108472915B (en) | Zero porosity NPR structure and tuning of location-specific NPR structure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |